A lot of grocery chains in India today are losing money, and in order to save their bottom line, they are moving from Indian domestic paper to stock lot paper. So stock lot paper on a kg to kg basis is cheaper than Indian paper, but it is not because of any inherent quality of that paper. The problem arises in how this paper is sourced. By definition, the DGFT has defined stock lot paper as any consignment coming into India without any description of the quality of paper inside or a menagerie of papers bundled together in a single consignment. So by interpretation of this definition, stock lot paper comes mixed. There is no chain of custody for its papers. It is usually rejected, an unwanted paper that is dumped in India.

The Madras High Court has also noted that the term stock lot represents any paper that is sold at a below-market price because it is being purchased in either a distress sale or a clearance sale. There is no document that really tells us why this clearance sale happened or what the problem is with this paper. It could be possible that the paper has a variation in GSM strength. It could be possible that it has failed the FDA guidelines. It has failed the food grade test. It has heavy metals in it. We just don’t know, and nobody can know. The implication of this is twofold.

The Importance of Chain of Custody and Consistency in Food Packaging Paper

First, regarding the health and welfare of your customers, Since there is no chain of custody for paper, even inside a single lot, paper can come from two different sources. Any food grade test done on a single reel is not applicable to any other reel of the same lot, let alone from lot to lot over a period of 12 months, and 12 months is approximately the time in which most national retail chains get the food grade test done.

The second problem with stock lot paper is that there is a very high chance of a variation in GSM or strength, so if you are paying 100 rupees for X number of paper bags, a variation of 10 GSM on a 60 GSM paper is a difference of 18%. So, instead of 100 bags, you will either get 82 if you are buying on a per kg basis, or whatever you are paying for those 100 bags, you could have gotten 118 bags out of that.

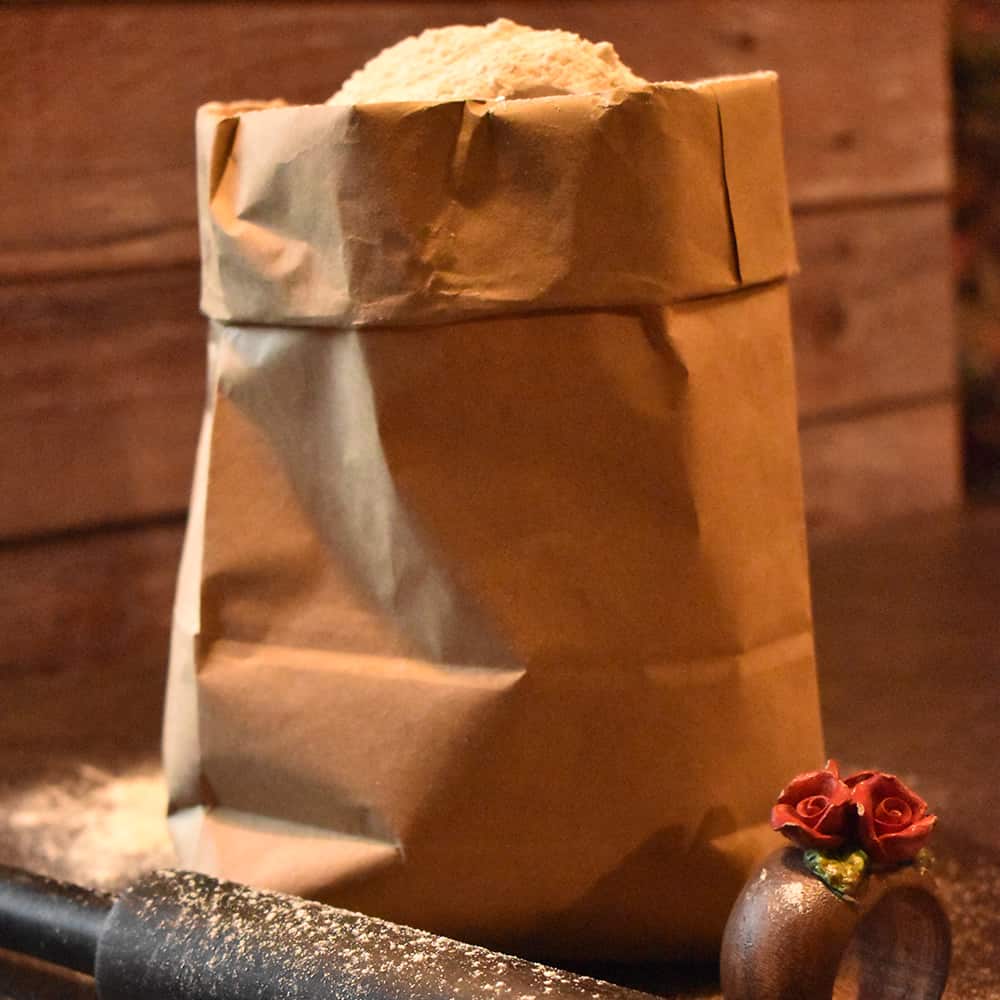

So, because of these two reasons, we feel stock lot paper is not at all suitable for use in food packaging or for saving money. The solution that is very clear in our minds is that all national retail chains, all grocery stores, and all home delivery chains use certified paper made in India, which has a chain of custody with every single lot. A common misconception is that Indian brown paper is cheaper than white paper. If you are looking to save on your bottom line, then don’t buy white paper.

If you are looking to purchase brown paper, the common misconception in India is that the paper has some odor. However, paper is not a commodity. If Swiss chocolatiers are using our paper, KFC, McDonald’s, Taco Bell, and all international brands are using our brown paper, then why can’t we use it ourselves?

Watch our Youtube video for better understanding